Discover the art of sheet metal fabrication with JR Michalski Heating & Air Conditioning, your local expert in Langhorne, PA. Learn how this vital service can enhance your home or business, providing custom solutions for your heating and cooling needs.

Mastering Sheet Metal Duct Fabrication: A Comprehensive Guide

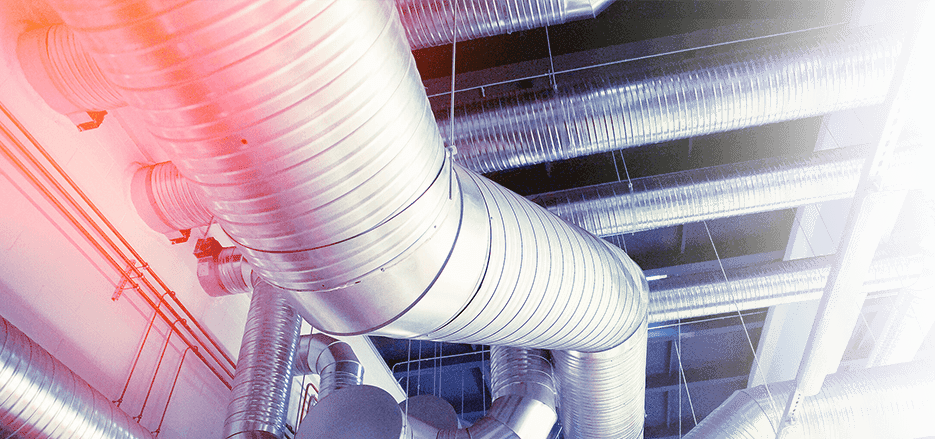

Sheet metal duct fabrication is a specialized process that involves the creation and assembly of ductwork used in HVAC systems. This fabrication is crucial in ensuring that air flows efficiently and effectively throughout residential, commercial, or industrial buildings.

Here’s an in-depth exploration of the sheet metal fabrication processes:

1. Material Selection

- The process begins with the selection of the right sheet metal materials, a crucial step in sheet metal manufacturing. Common choices include galvanized steel, aluminum, and sometimes, fiberglass.

2. Design and Layout

- A precise design is created based on the building’s HVAC needs. This design includes dimensions, shapes, and the layout of the ductwork. Advanced software is often used to optimize the duct layout for maximum efficiency and minimal noise.

3. Cutting and Shaping

- Once the design is finalized, large sheet metal parts are cut into the needed shapes and sizes. This is typically done using high-precision cutting tools like plasma cutters, shears, or laser cutting.

4. Forming

- After cutting, the metal sheets are formed into duct sections. This involves bending and joining edges to form sheet metal and the ducts’ desired shapes and sizes. Sheet metal fabrication techniques like folding, seaming, and flanging are used.

5. Assembly

- Individual duct sections are then assembled into a complete ductwork system. This might include the addition of flanges, joints, and other sheet metal components to connect the duct sections securely.

6. Insulation

- Insulation may be added to the ductwork to enhance energy efficiency and reduce heat loss. Insulated ducts help in maintaining the temperature of the air flowing through them, leading to more efficient heating and cooling.

7. Quality Checks and Finishing

- The fabricated ducts undergo rigorous quality checks to ensure they meet the required standards. These checks include examining the ducts for leaks, proper insulation, and overall integrity.

8. Installation

- Finally, the fabricated ductwork is installed in the building’s HVAC system. This step must be done with precision to ensure that the entire system functions efficiently and safely.

In the hands of experienced sheet metal fabricators like those at JR Michalski Heating & Air Conditioning, you can guarantee a fine-tuned process that ensures the effectiveness and longevity of your HVAC system.

This craftsmanship ensures that your residential or commercial space in Langhorne, PA, and the surrounding areas, enjoys optimal air distribution for a comfortable and energy-efficient environment.

FAQs on Sheet Metal Duct Fabrication

Is Metal Fabrication Hard?

Metal fabrication can be challenging, especially sheet metal duct fabrication, which requires precision and skill. It involves multiple steps – from designing and cutting to installing and forming sheet metal.

The complexity lies in ensuring that every piece of the ductwork is perfectly sized and shaped to fit the specific requirements of a building’s HVAC system.

What is the Best Sheet Metal for Fabrication?

The best sheet metal material for duct fabrication often depends on the specific requirements of the HVAC system and the environment where it will be installed. However, galvanized steel is widely preferred due to its durability, affordability, and resistance to corrosion.

Aluminum is another popular choice, especially where weight is a concern, as it is lighter than steel and also offers good corrosion resistance.

Is Welding the Same as Sheet Metal Fabrication?

Welding is a part of the sheet metal fabrication process but is not synonymous with it. Welding involves joining two sheet metals by melting the surfaces and adding a filler material to form a strong joint. It’s one of the techniques used in the assembly stage of sheet metal duct fabrication.

However, sheet metal fabrication as a whole encompasses a broader range of processes including sheet metal bending, cutting, forming, and assembling to create final products like ducts for HVAC systems.

How Long Does Sheet Metal Fabrication Take?

The time required for sheet metal duct fabrication varies depending on the project’s size and complexity. Simple projects might take only a few days, while more complex systems could require weeks.

Can Sheet Metal Ducts be Customized for Any Building?

Yes, one of the key advantages of metal sheet fabrication is its versatility. Ducts can be customized to any size, shape, and specification to fit the unique layout and requirements of any building.

This customization is crucial for maximizing the efficiency of an HVAC system and ensuring proper air distribution throughout the space.

Take the Next Step with JR Michalski!

Elevate your home or business’s HVAC efficiency with JR Michalski Heating & Air Conditioning. Experience our expert sheet metal duct fabrication tailored to your specific needs.

Contact us today for a consultation and see the difference professional craftsmanship makes. We’re here to ensure your comfort with quality, precision, and reliability.